THE CHALLENGE

THE CHALLENGEBearings in a continuous caster application can operate at temperatures around 100°C + with high loads and elevated water levels. Only a few greases can perform at a high level and reduce bearing wear in such conditions. However, steel mills looking to reduce their operating costs often turn to cheaper greases that carry upfront savings. This is not a cost effective solution in the long run.

THE SOLUTION

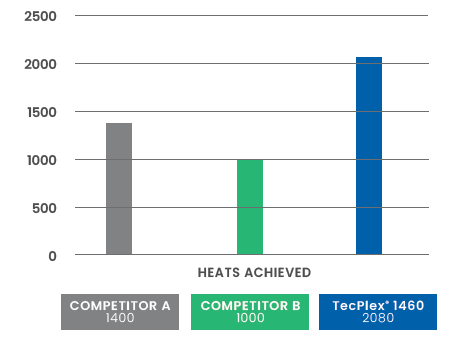

THE SOLUTIONDaubert’s TecPlex 1460 grease has proven to perform in extreme conditions that casters produce. As shown in the trial to the right, TecPlex 1460 steel mill grease offered superior wear protection in such conditions. This resulted in extended bearing life, optimized productivity and provided long-term operational savings.

THE RESULTS

THE RESULTSTecPlex 1460 showed minimal oxidation and almost no bearing wear after being exposed to twice as many heats as the competitors. Inspections of other calcium sulfonate greases determined that the bearings showed too much wear to be recoverable at the 3-month maintenance schedule at 1,000 heats. The other two competitors heavily oxidized and ultimately failed.