THE CHALLENGE

THE CHALLENGE• Many automotive OEMs demand additional corrosion protection beyond the protection that the cathodic dip coating (e-coat) currently provides.

• There can be thin film coatings in specific critical structural areas. These can be hem flange areas, welding spots or any complex structural areas with limited access or flow for the e-coat process.

• Torsion and vibration throughout the unibody or frame structure can result in fractured or chipping of the e-coat or hardshell coatings.

• Moisture and anti-icing chemicals can also damage critical structural components.

THE SOLUTION

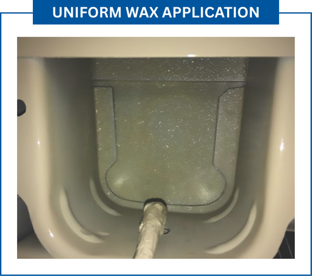

THE SOLUTION• Daubert has developed a specification flexible 100% solids cavity wax to be applied over critical areas within an e-coated unibody or body on frame applications.

• This seals any gaps or thin film areas.

• Air dry technology in these critical cavities result in a long-term corrosion protection solution.

• Multiple sag and penetrative capabilities to meet customer specific requirements.

THE RESULTS

THE RESULTSA large Japanese OEM is using Daubert’s 100% solids technology for advanced corrosion protection for a body-on-frame application. Additionally, multiple OEMs are using this technology to replace current solvent-based technologies. This is lowering applied costs, resulting in lower VOCs, and reducing carbon footprint. Please reach out to Daubert Chemical to discuss your specific project in more detail.

Download the Nox-Rust® 100% Solids product PDF to see technical specs, performance data, and more.